PE PP ABS Plastic Caps Shoe Heels Chroming Metallizing Coating Plant

Model No.︰EV series

Brand Name︰Hongfeng VAC

Country of Origin︰China

Unit Price︰US $ 41000 / set

Minimum Order︰1 set

Product Description

PE PP ABS Plastic Caps Shoe Heels Chroming Metallizing Coating Plant

EV Series

EV series, based on the thermal evaporation technology, are the most suitable coating system for producing reflective chrome like colors on kinds of plastic, glass, etc.

Main Specifications:

- Chamber size: φ 100mm-φ1800mm(Can be customized)

- 3-point vacuum level measuring,2-point temperature measuring

- High power evaporation transformaer achieving uniformed metal(usually aluminum) over different material of substrates.

- Different size, material, and types of susbtrates can be deposited by the tungsten & aluminum evaporation unit

- Auto-deposition control system for fully automated process.

- Center-driving or planetary substrate dome is selectable.

- Diffusion pump(or turbo molecular pumps) plus mechanical pumps for high vacuum pumping

Specifications

| Model | EV series |

| Vacuum Chamber | SUS304/Carbon Steel, φ1000mm-2000×1000-2000mm (H) |

| Substrate Dome Size | Depends on the customer's needs |

| Substrate Dome Rotation Speed | 10 rpm to 50 rpm (Variable) |

| Aluminum Evaporation Source | 1 or 2 sets |

| Vacuum System | Roughing Pump, Diffusion Pumps or Turbo Molecular Pump + Mechanical pumps |

Performance

| Ultimate Pressure | 2.0×10-3 Pa or lower |

| Pump Down Rate | 10 minutes (Atm. to 5.0×10-2 Pa) |

| Substrate Carousel | For holding the substrates |

Utility

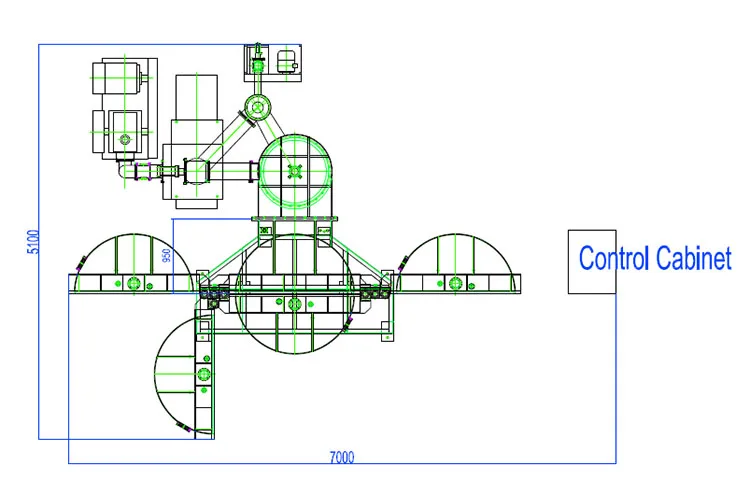

| Layout Dimensions | 5000mm (W)×6500mm (L)×3500mm (H) approx. |

| Power Requirements | 3-phase, 380V, 50/60Hz, 100-180kVA approx. |

| Cooling Water Flow Rate | 140/min. or greater |

| Compressed Air Pressure | 0.5MPa or higher |

| Gross Weight | 8500kg approx. |

Company Information

Packaging & Shipping

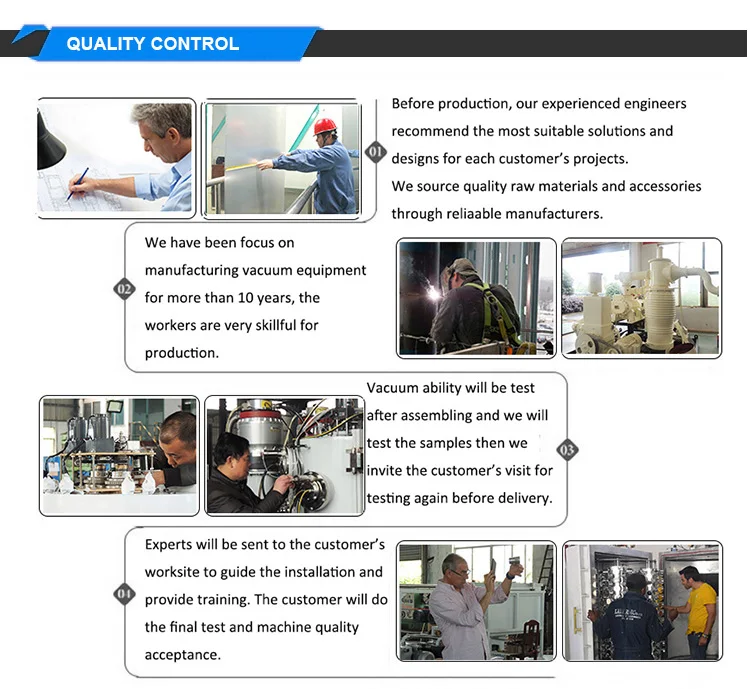

After the customer tested the machine and make sure the machine is no problem, we will take the machine apart. The solid packing can make sure you will receive a machine without any destroy.

Contact US

In order to help you choose the best suitable PVD coating machine, please try to reply my questions below, thanks for your cooperation.

Q1: What is your product, and the max. dimension?

Q2: The size of your processing material, your desired daily production capacity?

Product Image